Attendees at the 2012 HUG Symposium will experience Tuyen’s design first-hand at the event. “The design challenge not only lets our students apply their knowledge outside the classroom but also experience what it takes to become a future leader in the industry.”įive entrants who submitted interesting process designs that can solve critical plant business issues won the opportunity to attend their choice of one of two advanced UniSim Design training courses with their sponsoring tutors.Īn annual event, Honeywell’s UniSim Design Challenge is held in conjunction with the HUG Symposium. “The competition has given students a hands-on experience of real-life issues that manufacturing companies face,” said Dr Hien Nguyen Thi Minh, a professor at the PetroChemical and Catalysis Material Laboratory, Hanoi University of Science and Technology. UniSim Design helps engineers create and optimize plant designs and monitor asset performance, thus enabling stable operations and plant safety. Tuyen Dinh Quang’s design exemplifies the type of innovation that our customers want.” “In today’s environment, manufacturers need fresh ideas and innovations that solve real-world problems while maintaining high standards of plant safety, reliability and efficiency. “Our customers in the process manufacturing industry are always looking for new ways to perform their daily jobs more effectively and efficiently,” said Tony Cosgrove, Vice President-Sales APAC for Honeywell Process Solutions. Honeywell’s UniSim Design Suite is used by over 250 companies worldwide in the oil and gas, refining, petrochemical, chemical, and power industries. The model was tested for accuracy using crude oil from a Vietnamese refinery. It is expected that Tuyen’s design will help to maximise the gasoline yield produced.

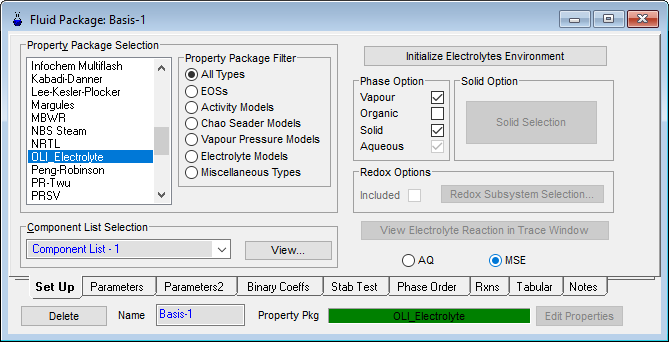

Span-Wagner is for pure CO2 systems, and EOS-CG is for rich-CO2 mixtures. Tuyen used UniSim Design Suite to simulate Fluidised Catalytic Cracking (FCC), the most important conversion process used in petroleum refineries. UniSim Design now includes the Span-Wagner and EOS-CG property packages, targeted at CO2 capture and storage applications (CCS). So, based on that, I prefer to set my Aspen Hysys flowsheet background as seem in old Hysys versions.

#UNISIM DESIGN USES SOFTWARE#

Tuyen Dinh Quang’s winning design used advanced process modelling software to simulate a key petroleum refinery process to help optimise production. The fact is that Aspen Hysys and Unisim Design has the same origin.

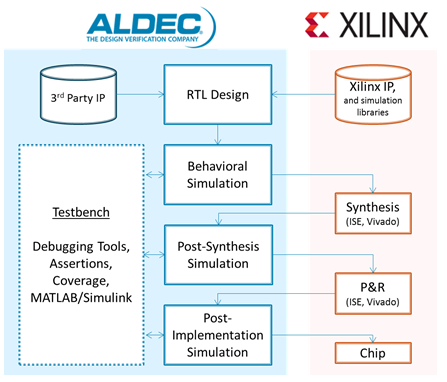

This presentation describes how you can benefit from the best practice in engineering workflow through the integration of UniSim Design and SmartPlant Enterprise.A chemical engineering student from the Hanoi University of Science and Technology was announced as the winner of the 2012 Asia Pacific UniSim Design Student Challenge today at the Honeywell Users Group (HUG) Asia-Pacific Symposium. The UniSim Design graphic is also published in a native SPE format which can be used as a starting point for creating the process flow diagrams. The process engineer will be able to use the simulation data in any product integrated with SPE to perform downstream tasks like P&ID and Instrumentation.

#UNISIM DESIGN USES SIMULATOR#

The UniSim Design simulator from Honeywell has been integrated with SPE to publish the heat and mass balance data for multiple design alternatives, revisions and cases. Honeywell UniSim® Design Suites model and a two-dimensional diesel-fed steam reformer ANSYS Fluent model. SmartPlant Enterprise (SPE) is a collection of products from Intergraph used to support elements of process engineering, however, does not include any process engineering calculation programs.

#UNISIM DESIGN USES UPDATE#

Therefore, it brings increased productivity and adds values to your business for the engineering solution to have the capacity to update the designs with the new information throughout the FEED process with consistent models. The information with different level of details gets added to the engineering design through the Front End Engineering Design (FEED) process. Socket uses current registered UniSim type library, in our case, it will use the last launched UniSim Design, easy to make mistakes. This creates a need for a flexible engineering solution to create various design alternatives, revisions and cases. The design solution cannot be explicitly determined and therefore is an iterative process that converges into a consistent design that must operate against a range of conditions (cases). Process engineering focuses on the design, operation and maintenance of chemical and material processes in a vast range of industries.

0 kommentar(er)

0 kommentar(er)